Polymer yaj viscosity ntsuas txiav txim siab extrusion thiab molding txheej txheem. Kev soj ntsuam viscosity ntawm lub sijhawm tiag tiag yog qhov tseem ceeb tshaj qhov ntsuas kub thiab ntsuas siab.

Overvi uaua ewof Extrusio uanMoldingProcess

Extrusion molding yog cov txheej txheem tsim tau zoo nyob rau hauv ntau qhov kev lag luam rau kev tsim cov khoom txuas ntxiv xws li cov kav dej, cov yeeb yaj kiab, cov ntawv, thiab lwm yam. Nws ua rau kev tsim cov duab sib luag ntawm cov duab sib luag hauv cov khoom zoo ib yam thaum lav kev ua haujlwm siab thiab cov khoom siv. Pom tseeb kev nce qib zoo li cov txheej txheem automation, kev saib xyuas lub sijhawm tiag tiag thiab kev saib xyuas cov txheej txheem rov ua dua tau txhim kho qhov tseeb thiab txo qhov cuam tshuam ib puag ncig los ntawm kev txo cov pov tseg.

Raugh Idea ntawmExtrusintawmMachine ib

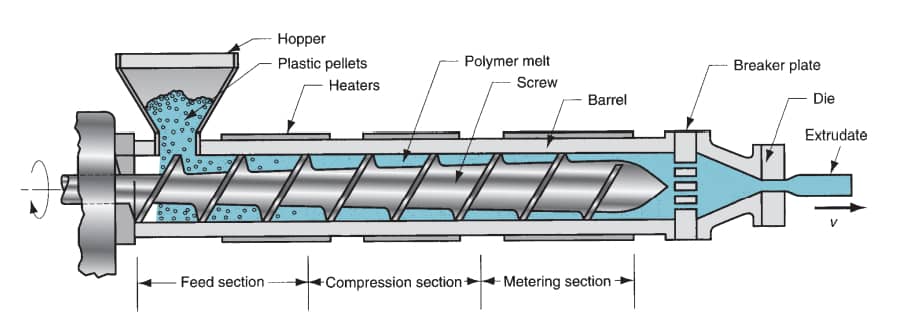

Lub tshuab extrusion muaj cov nram qab no: hopper, feeding ntswj, cua kub ntsiab lus thiab iav twj tso kua mis. Cov khoom yog pub rau hauv lub tshuab ntawm hopper. Ib tug tsis tu ncua rotating feeding ntsia hlau, tsav los ntawm lub cev muaj zog thiab gearbox, txav cov khoom raws li ib tug chim thiab los ntawm ib tug tuag. Cov khoom cua sov nyob ntawm lub thoob tswj qhov kub thiab txias kom soften thiab yaj cov khoom siv polymer. Tom qab tawm hauv qhov tuag, cov khoom molten nkag mus rau hauv pwm nrog ib los yog ntau kab noj hniav, qhov twg nws txias thiab solidifies rau hauv cov duab xav tau. Hauv qee lub tshuab, lub twj tso kua mis iav tau muab tso rau nruab nrab ntawm lub thoob thiab tuag kom ntseeg tau tias lub siab zoo ib yam ntawm cov khoom tawm.

Ntsiab viscosity ntsuas cov ntsiab lus ntawm lub tshuab Extrusion

Hopper Exit / Pub Zone: Ntsuas qhov pib yaj viscosity thaum lub polymer pib mos.

Melting Zone (Nruab nrab Barrel): Captures txoj kev hloov mus rau lub xeev molten tag nrho.

Kev ntsuas Zone(Ua ntej iav twj tso kua mis los yog tuag): Kev ntsuas polymer yaj viscosity ntsuas raws li kev ua haujlwm shear tus nqi.

Tuag Nkag: Muab cov ntaub ntawv yaj viscosity tiag tiag ntawm lub sijhawm extrusion.

Nkag siab txog Polymer Melt thiab Viscosity

Polymer yaj yog dab tsi?

Nws yog ib qho polymer rhuab mus rau lub xeev molten, nthuav tawm cov khoom ntws uas tso cai rau shaping los ntawm extrusion lossis molding. Covyaj viscosity ntawm polymers-Qhov kev tiv thaiv tsis txaus - nyob ntawm qhov hnyav molecular, qhov kub thiab txias, shear rate, thiab additives, cuam tshuam cov khoom kawg lub zog thiab tiav. Hauvpolymer extrusion txheej txheem, qhov twg molten polymer yog extruded los ntawm ib tug tuag, thiab nyob rau hauv kev txhaj tshuaj molding, qhov twg nws puv pwm nyob rau hauv siab, tswj kev pom.yaj viscosityyog qhov tseem ceeb. Ib txwmpolymer melt viscosity ntsuastxoj kev, xws li off-line capillary rheometry, feem ntau lag vim qeeb, ua rau kev hloov mus rauhauv kabviscometer rau polymersrau kev nkag siab ntawm lub sijhawm.

Kev sib tw hauv Polymer Extrusion thiab Txheej Txheem Tswj

Covpolymer extrusion txheej txheemthiab txhaj tshuaj molding ntsib teeb meem tseem ceeb hauv kev tswj kom zoo ib yamyaj viscosity. Variability vim thermal gradients thiab fluctuating shear tus nqi tuaj yeem ua rau tsis sib xwsyaj viscosity ntawm polymers, ua rau muaj teeb meem xws li nto irregularities los yog voids nyob rau hauv extruded profiles. Loj-scale extrusion kab tawm tsam nrog uniformpolymer melt viscosity ntsuashla kev khiav, ua raws li kev tswj hwm tus txheej txheem. Nyob rau hauv high-speed txhaj molding, phau ntawv hloov kho tsis ua raws li lub sij hawm sai sai, pheej hmoo ua tsov rog los yog ua tsis tiav. Cov kev cov nyom no qhia txog qhov yuav tsum tau ua kom tiavpolymer viscometersystems, xws li covTsis siv neeg polymer viscometer, muab cov ntaub ntawv ntawm lub sijhawm tiag tiag thiab kov yeej cov kev txwv ntawm cov txheej txheem ib txwm muaj.

Vim li cas Melt Viscosity Monitoring Matters

Melt viscosity ntsuas yog qhov tseem ceeb hauv cov txheej txheem polymer extrusion thiab txhaj tshuaj molding rau ntau yam. Nyob rau hauv extrusion, zoo ib yam yaj viscosity kom tsis tu ncua tuag sau thiab tiv thaiv tsis xws luag xws li nto irregularities los yog tuag swell. Hauv kev txhaj tshuaj molding, nws cuam tshuam rau pwm txhaws, qhov zoo, thiab lub sijhawm voj voog, qhov kev hloov pauv tuaj yeem ua rau muaj kev sib tsoo lossis ua tsis tiav. Kev saib xyuas lub sijhawm tiag tiag tso cai rau cov neeg ua haujlwm kho qhov kub thiab txias, siab, lossis cov khoom sib xyaw ntawm ya, ua kom zoo siv lub zog thiab txo cov pov tseg - cov kev txhawj xeeb tseem ceeb raws li cov kev cai carbon nruj hauv 2025.

Lub complexity ntawm polymer yaj viscosity ntsuas tshwm sim los ntawm non-Newtonian xwm ntawm polymer melts, qhov twg viscosity txawv nrog shear npaum li cas thiab thermal keeb kwm. Cov txheej txheem ntawm inline polymer-melt viscometer systems hais qhov no los ntawm kev muab cov ntaub ntawv txuas ntxiv, ua kom cov txheej txheem tswj hwm cov txheej txheem offline tsis tuaj yeem sib tw.

Lonnmeter's Expertise in Melt Viscosity Monitoring

Nrog ntau tshaj kaum xyoo ntawm kev paub,Lonnmeter, ib tug cojPolymer viscometer tsum, tau tsim nws tus kheej ua tus pioneer hauvkev soj ntsuam viscosity. Lawv cov kev txawj ntse nthuav dav kev kub siab, kub kub extrusion kab thiab txhaj tshuaj molding chaw, hais txog cov kev xav tau ntawm ntau hom polymers xws li polyethylene, polypropylene, thiab PET.

Khoom Solutions

Lonnmeter muaj kev txiav-ntugpolymer yaj viscometerkev daws teeb meem rauyaj viscosity xyuas. CovInline Viscometeryog tsim los rau perpendicular lossis parallel installation hauv extrusion tshuab, ntsuasyaj viscositymus txog 100,000 cP·s thiab kub txog li 300 ° C, tsis cuam tshuam los ntawm kev hloov pauv.

Customization yog ib qho tseem ceeb ntawm Lonnmeter cov khoom, nrog rau cov kev xaiv rau threaded los yog flanged kev twb kev txuas thiab cov ntaub ntawv tso zis ntawm 4-20mA los yog RS485, integrating seamlessly nrog automation systems. Nyob rau hauv extrusion, lub teeb perpendicular kom muaj kev cuam tshuam tsawg kawg nkaus.

Cov txiaj ntsig ntawm Lonnmeter's Melt Viscosity Solutions

Quality Assurance:Lub sijhawm tiag tiagpolymer melt viscosity ntsuasxyuas kom meej tsis muaj qhov tsis xws luag extrudates thiab molded qhov chaw.

Nqi Efficiency:Txo cov khoom pov tseg thiab kev saib xyuas qis dua cov nqi ua haujlwm.

Kev txuag hluav taws xob:Precise adjustments optimize zog siv.

Txheej txheem Flexibility:Compatibility nrog ntau yam polymers txhawb ntau yam kev xav tau ntau lawm.

Txhim khu kev ruaj ntseg:Kev tshawb pom ntxov ntawm viscosity anomalies tiv thaiv cov cuab yeej siv.

FAQs

Vim li cas melt viscosity tseem ceeb dua qhov kub thiab txias?

Melt viscosity ncaj qha cuam tshuam rau yaj ntws, tuag puv, thiab cov khoom sib xws, feem ntau tshaj qhov cuam tshuam ntawm qhov kub thiab txias. Kev ntsuas kom zoo polymer yaj viscosity tiv thaiv tsis xws luag xws li warpage lossis tuag o, ua rau nws tseem ceeb rau kev tswj cov txheej txheem.

Lonnmeter ua kom cov ntaub ntawv sib koom ua ke li cas?

Tsis siv neeg polymer viscometer integrates ntawm 4-20mA los yog RS485 raws tu qauv, muab cov ntaub ntawv real-time los tswj cov tshuab. Nws cov keeb kwm onboard, nkag tau los ntawm software, muab keeb kwm kev pom, tshaj li cov kev txwv viscometer polymer.

Dab tsi cuam tshuam rau yaj viscosity ntawm polymers?

Lub yaj viscosity ntawm polymers yog cuam tshuam los ntawm molecular hnyav, kub, shear npaum li cas, thiab muaj cov additives los yog fillers. Qhov hnyav dua molecular thiab qhov kub qis dua feem ntau nce viscosity, cuam tshuam rau cov txheej txheem polymer extrusion.

Melt viscosity xyuas yog lub hauv paus ntawm cov txheej txheem polymer extrusion thiab txhaj tshuaj molding, ua kom zoo thiab ua haujlwm zoo. Nrog Lonnmeter qhov kev tshaj lij pov thawj thiab qib siab viscometer rau polymers, cov tuam txhab lag luam tuaj yeem kov yeej cov kev sib tw hauv cov txheej txheem tswj thiab ua kom zoo tshaj plaws. Thov ib daim ntawv tsocai hnub no los ntawm tus neeg muag khoom uas ntseeg siab polymer viscometer!

Post lub sij hawm: Lub Xya hli ntuj-31-2025