Lubricants tau siv dav hauv kev lag luam xws li kev lag luam tsheb, tshuaj lom neeg, kev tsim kho, textile, infrastructure, kev ua liaj ua teb, mining thiab roj drilling rau lawv cov kev ua tau zoo hauv kev hnav tsis kam, lubrication thiab corrosion kuj. Flowabilty kev txhawj xeeb xws li siab dhau lossis qis dhau lawm tuaj yeem ua rau cov cuab yeej siv lub neej luv thiab nce nqi kho. Nkag mus rau hauv cov ntsiab lus ntxiv nrog Lonnmeter nrhiav cov kev daws teeb meem zoo tshaj plaws rau kev ntsuas qhov nrawm nrawm nrawm hauv cov roj sib xyaw lossis cov txheej txheem tsim khoom. Ua raws li txoj kev lag luam automation.

Dab tsi yog Viscosity Index (VI) ntawm Lubricant?

Viscosity Index (VI) yog ib qho kev ntsuas tseem ceeb uas txhais tau hais tias lub roj nplua nyeem muaj peev xwm tswj tau cov viscosity zoo ib yam thoob plaws qhov kub thiab txias, yog ib qho tseem ceeb rau kev ua kom ntseeg tau qhov kev ua tau zoo hauv kev ua haujlwm sib txawv. VI siab qhia tau hais tias tsawg viscosity hloov nrog kub hloov, ua rau nws zoo tagnrho rau cov kev siv xws li hydraulic systems los yog engine raug rau huab cua huab cua. Hloov pauv, VI roj nplua nyeem qis ua rau muaj kev hloov pauv ntawm cov viscosity, uas tuaj yeem cuam tshuam kev ua haujlwm. Piv txwv li, cov roj ntxhia cov pa ib txwm muaj VI ntawm 95-100, thaum cov roj ntxhia ua kom zoo siab txog li 120, thiab cov roj hluavtaws tuaj yeem ua tiav VIs tshaj 250.

Kev Tshawb Fawb Kev Ua Lag Luam & Kev Siv Khoom Siv

Txhua yam ntawm lubricants yuav tsum tau xa cov kev ua tau zoo ib yam txawm tias nyob rau hauv qhov xwm txheej hnyav. Cov txheej txheem tsim cov roj nplua nyeem tau nce siab kom ua tau raws li cov qauv nruj, uas tau tsav los ntawm kev thov nce rau cov khoom tshwj xeeb thiab lub sijhawm xa khoom luv.

Lubricant blending thiab lubricant oil manufacturing txheej txheem cia siab ntau rau kev tswj cov roj lubricating ceev thiab viscosity kom ntseeg tau cov khoom lag luam. High viscosity lubricants ua tau zoo nyob rau hauv daim ntawv thov hnyav, thaum uas tsis muaj viscosity lubricants yog haum rau high-speed, low-load systems. AdvancedLube roj viscosity meterspab cov tuam txhab lag luam kom ua tau raws li cov kev cai sib txawv no thaum ua kom pom kev ua haujlwm zoo, txo cov khib nyiab, thiab ua raws li cov qauv.

Lub Viscosity Index ntawm Lubricant Txiav Txim Li Cas?

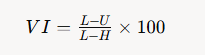

Kev txiav txim siab Viscosity Index suav nrog txheej txheem txheej txheem. Cov mis rau VI suav yog:

Qhov twg:

- U yog lub lubricant viscosity ntawm 40 ° C.

- L yog viscosity ntawm 40 ° C ntawm cov roj siv nrog VI = 0, sib piv cov roj nplaum lub viscosity ntawm 100 ° C.

- H yog viscosity ntawm 40 ° C ntawm cov roj siv nrog VI = 100, sib piv cov roj nplaum lub viscosity ntawm 100 ° C.

Rau cov roj viscosity siab (kinematic viscosity ntawm 100 ° C > 70 cSt), hloov logarithmic mis yog siv los xyuas kom meej. Txoj kev no tso cai rau cov tuam txhab tsim kom muaj nuj nqis ntawm lubricant qhov kub thiab txias, kom ntseeg tau tias nws ua tau raws li cov kev xav tau tshwj xeeb ntawm cov ntawv thov hauv cov txheej txheem lubricant.

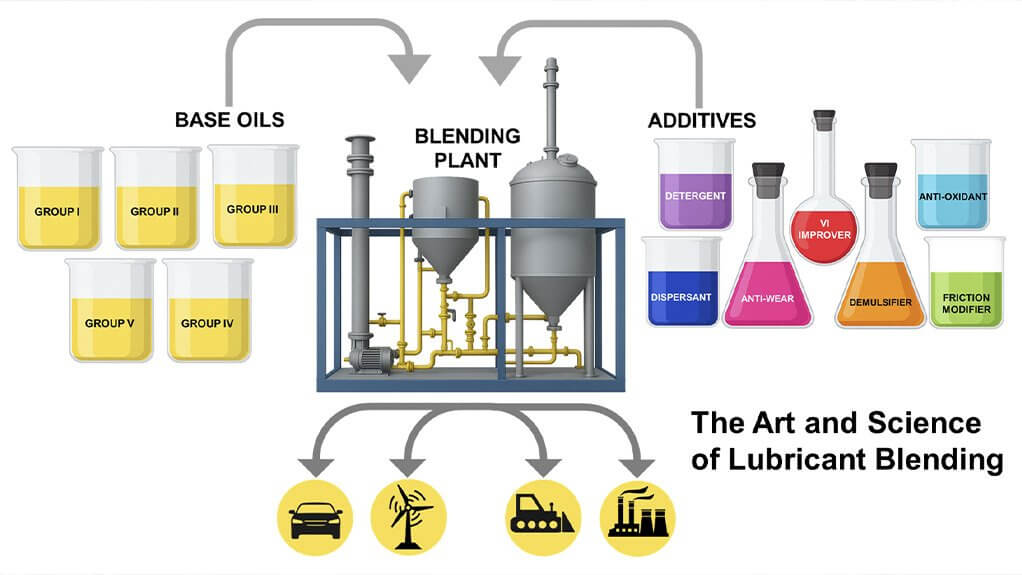

Lube Roj Blending & Manufacturing txheej txheem

Cov roj nplua nyeem sib xyaw yog cov txheej txheem sib txawv ntawm cov khoom siv raw xaiv, sib tov, thiab tswj kom zoo. Cov roj hauv paus - ntxhia, hluavtaws, lossis semi-synthetic - yog muab los ntawm cov roj crude refining los ntawm lub tshuab nqus tsev distillation, hnyav extraction, thiab hydrofinishing kom ua tiav cov khoom xav tau xws li viscosity, viscosity index, thiab ncuav point. Cov roj hauv paus no ua ke nrog cov khoom siv ntxiv, xws li viscosity index improvers, anti-wear agents, detergents, thiab antioxidants, los txhim kho cov yam ntxwv zoo li thermal stability thiab corrosion resistance. Cov txheej txheem ntawm lubricant manufacturing muaj xws li:

- Base Oil Selection: Xaiv cov ntxhia los yog cov roj hluavtaws raws li daim ntawv thov xav tau.

- Additive Integration: Incorporating additives like viscosity modifiers to tailor properties.

- Blending: Sib tov nyob rau hauv kev tswj tej yam kev mob siv lub tank loj nrog stirrers los xyuas kom meej homogeneity.

- Kev Tswjhwm Zoo: Kev ntsuas viscosity, ntom ntom, flash point, thiab lwm yam tsis ua raws li cov qauv.

- Ntim thiab Xa Khoom: Lub raj mis los yog lub thoob rau kev xa khoom lag luam.

Cov txheej txheem kev ua kom zoo no ua kom cov roj nplua nyeem ua tau zoo hauv cov ntawv thov xws li tsheb cav mus rau cov tshuab ua haujlwm, nrog cov roj lubricating ntom ntom thiab viscosity ua qhov ntsuas qhov tseem ceeb.

High Viscosity vs. Low Viscosity Lubricating Roj

Kev xaiv ntawm high viscosity lubricating roj thiab tsawg viscosity lubricating roj hinges ntawm daim ntawv thov kev ua haujlwm xav tau. High viscosity lubricants yog qhov zoo tagnrho rau kev siv lub luag haujlwm hnyav, xws li cov roj iav lossis roj siv hauv cov khoom siv los yog steel kev lag luam bearings, qhov twg lawv:

- Tsim cov yeeb yaj kiab tiv thaiv kom tsis txhob muaj kev sib txhuam thiab hnav hauv qhov hnyav.

- Txhim khu lub peev xwm load-bearing, txhawb nqa cov tshuab hnyav.

- Cuam tshuam cov kab mob xws li av lossis cov khib nyiab hlau, tiv thaiv qhov chaw puas.

- Ua kom ruaj khov ntawm qhov kub thiab txias, ua kom ntseeg tau qhov kev ua tau zoo.

Txawm li cas los xij, cov roj nplua nyeem ntau dhau tuaj yeem ua rau muaj zog siv zog thiab cov khoom siv lim. Nyob rau hauv sib piv, tsis tshua muaj viscosity lubricants haum high-speed, low-load daim ntaub ntawv xws li automotive engines los yog hydraulic systems, muab:

- Txhim kho flowability kom muaj txiaj ntsig zoo thiab kev ua haujlwm txias pib.

- Txo kev siv hluav taws xob vim muaj kev sib txhuam sab hauv.

- Txhim kho cua sov dissipation nyob rau hauv high-speed systems.

Txawm li cas los xij, cov roj viscosity tsawg tuaj yeem ua tsis tau qhov kev tiv thaiv txaus nyob rau hauv cov khoom hnyav, ua rau hnav.

Kev ua haujlwm tsis zoo

Kev cuam tshuam Defoaming thiab Demulsibility: Ua rau kev ua haujlwm tsis zoo.

Nce kev sib txhuam & cua sov

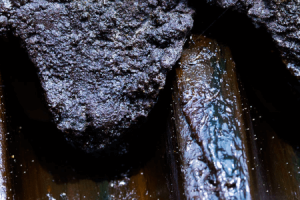

Ntau thickness impedes ntws, accelerating oxidation thiab ua cov kua roj vanish los yog sludge.

Kev pheej hmoo tshwm sim los ntawm Siab dhau lossis qis dhau viscosity

Tsis raug viscosity hauv lubricants tuaj yeem ua rau muaj teeb meem kev ua haujlwm tseem ceeb, tsom iav qhov teeb meem pom hauv cov txheej txheem xws li cov txheej txheem penicillin fermentation qhov twg kev tswj hwm yog qhov tseem ceeb. High viscosity lubricating roj ua rau muaj kev pheej hmoo xws li:

- Kev siv hluav taws xob ntau dua: yuav tsum muaj lub zog ntau dua los tiv thaiv kev tiv thaiv, nce nqi.

- Kev Ua Haujlwm Tsis Zoo Txias-Start: Txo cov twj tso kua mis txaus ntshai ua rau cov khoom puas tsuaj ntawm qhov kub qis.

Conversely, tsis tshua muaj viscosity lubricating roj tuaj yeem ua rau:

- Kev tsim cov yeeb yaj kiab tsis txaus: Kev tiv thaiv tsis txaus ua rau muaj kev hnav thiab tiv thaiv tsis ua haujlwm.

- Heightened Contamination Sensitivity: Cov roj nyias nyias tsis muaj txiaj ntsig zoo ntawm cov khoom khib nyiab.

- Ua kom muaj kev sib txhuam thiab cua sov: Txhawb oxidation thiab txo cov roj lubricating lifespan.

Cov kev pheej hmoo no qhia txog qhov xav tau rau cov roj nplua nyeem cov roj sib xyaw ua ke tswj kev siv lub sijhawm viscosity xyuas kom ntseeg tau tias kev ua haujlwm zoo ib yam.

Tus nqi ntawm viscosity ntsuas hauv Automation txheej txheem kab

Incorporating real-time viscosity ntsuas nyob rau hauv blending rau hauv automated txheej txheem kab transforms lub lubricant manufacturing txheej txheem, muab:

- Precision Blending: Ua kom homogeneity, tiv thaiv cov khoom siv tshwj xeeb thiab raug nqi rov ua dua.

- Tus nqi Efficiency: Txo kev siv hluav taws xob, kev tsim cov roj sloping, thiab kev pab cuam ntawm phau ntawv.

- Kev Ua Haujlwm Zoo: Ua raws li cov qauv zoo li ASTM D445, ua kom muaj kev lees paub hauv khw.

- Txheej Txheem Optimization: Txo cov sij hawm sib xyaw thaum ua tiav cov khoom sib xws.

- Scalability: Txhawb kev hloov pauv seamless los ntawm kev tsav mus rau kev tsim tawm tag nrho.

- Proactive Issue Detection: txheeb xyuas cov kab mob sib kis lossis sib xyaw ua ke tam sim, txo qis sijhawm.

Los ntawm kev tswj cov viscosity automating, cov tuam txhab ua tiav cov khoom lag luam hauv lub sijhawm, txhim khu kev yooj yim, thiab ua tau raws li cov kev xav tau ntawm kev lag luam kev sib tw, zoo li qhov yuav tsum tau muaj nyob rau hauv tas li fermentation ntawm penicillin.

Cov kev sib tw nrog cov txheej txheem kev soj ntsuam

Kev soj ntsuam cov txheej txheem ib txwm muaj nyob rau hauv kev sib xyaw roj nplua nyeem yog siv ntau ntawm cov qauv offline thiab kuaj raws li kev sim, xws li Saybolt Universal Viscometer, uas nthuav tawm cov teeb meem tseem ceeb:

- Lub Sijhawm Ncua Sijhawm: Sampling thiab lab tsom xam qhia txog kev lag luam, cuam tshuam kev hloov kho lub sijhawm.

- Inaccuracy: Kub thiab shear variations thaum sampling cuam tshuam cov ntaub ntawv kev ntseeg siab.

- Kev siv zog ua haujlwm: Kev ntsuas phau ntawv ua rau nce nqi ua haujlwm thiab kev pheej hmoo ntawm tib neeg yuam kev.

- Kev pheej hmoo ntawm kev kis kab mob: Cov qauv ntsuas tsis sib xws tuaj yeem ua kom paub qhov yuam kev lossis kev sib kis.

- Tsawg Scalability: Offline txoj kev tawm tsam kom ua raws li cov kev xav tau ntau lawm.

Cov kev txwv no ua rau cov txheej txheem ib txwm ua tsis zoo rau niaj hnub lub roj sib xyaw cov nroj tsuag, qhov twg ceev, raug, thiab automation yog qhov tseem ceeb rau kev tswj kev sib tw.

Qhov tseem ceeb ntawm Real-Time ntsuas hauv kev sib xyaw

Real-time viscosity ntsuas revolutionizes lubricant blending txheej txheem los ntawm kev muab tam sim, yog cov ntaub ntawv uas tsav efficiency thiab zoo. Cov txiaj ntsig tseem ceeb suav nrog:

- Kev tshem tawm ntawm Reblending: Kev soj ntsuam tas li ua kom muaj kev sib xyaw ntawm cov khoom tshwj xeeb, txo cov nqi khib nyiab thiab hluav taws xob.

- Txo cov kev cuam tshuam ntawm phau ntawv: Automation txo tus neeg teb xov tooj kev koom tes, txo cov nqi thiab kev ua yuam kev.

- Optimized Blending Sijhawm: Kev kho lub sijhawm tiag tiag tiv thaiv kev sib xyaw ua ke, txuag sijhawm thiab peev txheej.

- Logistical Efficiency: Onsite tsom xam txo qhov kev xav tau ntawm qhov chaw kuaj sim, txiav nqi shipping.

- Environmental Benefits: Maximizes kev siv roj, txo cov khib nyiab thiab ib puag ncig.

- Enhanced Diagnostics: Taug qab cov kev hloov pauv ntawm cov roj, ua kom pom ntxov ntawm kev sib kis lossis degradation.

Lonnmeter Khoom Siv Tshuaj: Lube Roj Viscosity Meter

Lonnmeter's lube roj viscosity ntsuas tau tsim los ua kom tau raws li qhov xav tau nruj ntawm cov txheej txheem roj lubricant, muab cov kev daws teeb meem rau kev saib xyuas lub sijhawm. Cov yam ntxwv tseem ceeb muaj xws li:

- Wide Viscosity Range: Ntsuas 10–10,000,000 cP, haum rau kev sib xyaw ua ke.

- High-Temperature Resilience: Ua haujlwm txog li 350 ° C, haum rau qhov chaw siab-shear.

- Integrated Temperature Monitoring: Siv cov roj viscosity meter muaj qhov tseeb rau qhov ntsuas kub-paub cov viscosity nyeem.

- Seamless Automation: Ua ke nrog PLC thiab DCS systems rau kev tswj hwm.

- Robust Design: Compact, txij nkawm-dawb sensors uas tsis muaj consumables, kom ntseeg tau.

- Cov Ntaub Ntawv Logging thiab Kev Ruaj Ntseg: Tsis siv neeg kaw cov ntaub ntawv nrog cov lej sijhawm, tiv thaiv kev hloov pauv tsis raug cai thiab ua kom muaj kev tsom xam.

Lonnmeter's meters, zoo ib yam li Rheonics 'SRV thiab SRD, muab inline viscosity thiab ntom ntsuas, tshem tawm qhov tsis raug ntawm cov txheej txheem ib txwm muaj xws li Saybolt viscometer. Lawv lub peev xwm los lis cov dej tsis-Newtonian ua kom zoo ib yam hauv cov roj nplua nyeem, txhawb kev siv los ntawm kev tsim tawm mus rau qhov kawg.

Mastering viscosity tswj muab qhov zoo ib yam, txo cov nqi, txhim khu kev ua kom muaj zog, thiab ua kom muaj kev ua raws li cov qauv zoo li ASTM D445. Hu rau Lonnmeter hnub no los tshawb txog lawv cov kev ntsuas viscosity hauv lub xeev thiab hloov koj cov txheej txheem ntau lawm!

Post lub sij hawm: Aug-14-2025